Unpacking The Importance Of Lipid Nanoparticle Production Platforms

Maik Jornitz, BioProcess Resources LLC

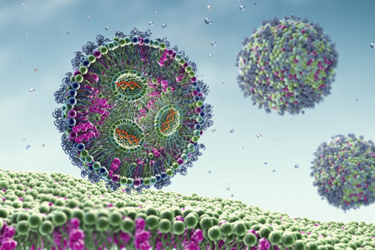

Lipid nanoparticles (LNPs) have emerged as crucial delivery vehicles for nucleic acids, garnering significant attention and investment due to their successful role in mRNA-based therapeutics and vaccines. LNPs, primarily composed of natural biocompatible ingredients, efficiently encapsulate and transport nucleic acids, enabling their effective delivery into the cytoplasm of target cells.

Initially rooted in liposomes, LNPs have evolved from these lipid-based delivery systems, with a key focus on ionizable lipids to optimize their efficacy. The choice of ionizable lipids profoundly influences LNP formulation, affecting the stability and effectiveness of the therapeutic payload. Researchers are actively engaged in designing novel cationic lipids to enhance the stability and immune response of nucleic acids within LNPs.

While ionizable lipids play a central role, the overall lipid composition within LNPs can impact various aspects of their performance, including targeting specificity and cellular uptake efficacy. Future developments may involve the conjugation of targeting moieties onto LNPs for active, customizable targeting, potentially increasing efficacy and reducing off-target effects.

As much as LNP development has progressed, it appears that the existing processing platforms for LNPs lack efficiency, appropriate controls, and yield optimization. This inefficiency in batch processes can lead to challenges such as low productivity, inconsistent results, and difficulties in maintaining quality standards.

The Past And Current Processing State

Currently, LNP processing happens as a batch process with limited control and inefficient online analytics, resulting in variable quality outputs. In batch LNP processing, several drawbacks and limitations can impede efficiency and productivity compared to continuous processing methods.

Some of the disadvantages of batch LNP processing include:

- Time and Labor Intensive: As batch processes typically involve multiple unit operations that need to be carried out sequentially, longer processing times and increased labor requirements are needed. This can result in slower production rates and higher operational costs.

- Inefficient Resource Utilization: Batch processing often requires the use of holding or storage tanks to accommodate intermediate products at various stages of the production process. This can lead to inefficiencies in resource utilization, as these tanks may remain idle during certain stages of the production cycle, require a larger vital classified footprint, and result in lower yields.

- Risk of Contamination: The repeated transfer of materials between different unit operations in batch processing can increase the risk of contamination, leading to potential quality issues or product variability. Contaminants introduced at various stages could impact the final quality and efficacy of the LNPs produced.

- Difficulty in Process Control: Monitoring and controlling key parameters in batch processing, such as temperature, pressure, and mixing dynamics, can be more challenging compared to continuous processes. Variations in process conditions between different batches may lead to inconsistencies in the final product.

- Limited Scalability: Batch processes may face limitations in scalability, as increasing production volumes often requires significant adjustments to equipment, time-consuming validation processes, and potential batch-to-batch variations. This can hinder the ability to efficiently meet growing market demands.

- Higher Energy Consumption: The start-stop nature of batch processing can result in higher energy consumption compared to continuous processes, where equipment operates continuously in a more regulated manner. This inefficiency can lead to increased operational costs and negative environmental impacts.

From Batch To Continuous Processing

In response to the disadvantages associated with batch processing of LNPs and the increasing demand for higher production capacities and critical quality standards, the development of new processing innovations has become a pressing priority in the field. Manufacturers are recognizing the need for more efficient, scalable, and controlled production methods to meet the growing market requirements and regulatory standards.

Some of the key drivers pushing for new processing innovations in the production of LNPs include:

- Efficiency Enhancement: The need to improve operational efficiency, reduce processing times, and optimize resource utilization is pushing manufacturers to explore innovative processing technologies that can streamline production workflows and minimize waste.

- Scalability Requirements: With the rising demand for LNPs in various industries, including pharmaceuticals, cosmetics, and food supplements, there is a critical need for scalable production solutions that can easily adapt to changing production volumes without compromising product quality.

- Quality Control: Meeting stringent quality standards and ensuring product consistency and uniformity are paramount in industries where LNPs are utilized. New processing innovations are expected to incorporate advanced monitoring and control systems to enhance quality assurance throughout the production process.

- Cost Efficiency: Developing cost-effective processing solutions that can deliver high-quality LNPs at competitive prices is essential for manufacturers looking to maintain their competitive edge in the market. Innovations that optimize resource consumption and reduce operational costs are highly sought after.

- Regulatory Compliance: Adhering to regulatory requirements and guidelines is crucial for ensuring product safety and efficacy. New processing innovations are expected to offer built-in compliance features that facilitate adherence to industry regulations and standards.

By investing in research and development efforts to create novel processing technologies, such as continuous manufacturing platforms, automated systems, and advanced monitoring tools, manufacturers can address these challenges and fulfill the increasing demand for LNPs while meeting the stringent quality and efficiency needs of the industry.1

Continuous nanoparticle generation technologies can integrate and consolidate all unit operations into a single streamlined process within a closed system. This consolidation eliminates the need for multiple individual unit operations and the associated holding or storage tanks required in batch processing. By combining all the necessary production steps into a continuous flow system, the manufacturing process becomes more efficient, with reduced handling steps, shorter processing times, and minimized risks of contamination or product variability.

Unlike traditional microfluidics batch processing, the technologies entering the LNP industry are integrated to form a continuous processing skid, eliminating the necessity for open transfers and human intervention, avoiding potential contamination sources. Continuous jet turbulent mixing technology plays a pivotal role in optimizing production speeds by rapidly mixing lipids and nucleic acids to efficiently create the most uniform size LNPs. These systems offer incorporated process analytical technologies for in-line particle size monitoring and control, ensuring consistent product quality throughout the closed-loop process.2

These innovations have the potential to revolutionize the way LNPs are produced, setting new standards for productivity, quality, and sustainability in nanoparticle manufacturing. As continuous nanoparticle production represents a novel concept in the pharmaceutical sector, the suppliers are dedicated to collaborating closely with end users.

Again, essential in this trial work is the process control, data capture, and analysis to design the optimal process and operating parameters. These will help overcome the limitations associated with batch processes and enable the manufacturing of LNPs with higher efficiency and reliability. It is imperative to clarify and showcase the functionality of the technology and the advantages it offers.

Conclusion

Ongoing developments in the lipid composition of LNPs are expected to further enhance their performance and broaden their applications in the realm of vaccines and therapeutics. These advancements have the potential to revolutionize the medical landscape by enabling a shift toward curative approaches to diseases, raising the possibility of transformative treatments. Indeed, as LNPs continue to see rapid advancements and increased utilization in various industries, the role of advanced manufacturing processes becomes even more pivotal in guaranteeing the quality, scalability, and efficiency of LNP products. Innovative manufacturing techniques are essential for meeting the evolving needs and demands of the market while maintaining high standards of product performance and safety. By leveraging cutting-edge technologies and adopting best practices in manufacturing, companies can ensure the consistent delivery of high-quality, scalable, and cost-effective LNP products to meet the diverse needs of industries ranging from pharmaceuticals to personal care and beyond.

References:

- Costa, T., Ph.D., and Pasek, W. (2023) Facilitating Lipid Nanoparticle Production with a Unique Continuous Manufacturing Solution, Pharma’s Almanac, PAO-04-23-CL-05

- Costa, T., Ph.D., (2021) Enhanced Process Control For Lipid-Based Nanoparticles: LNPS and Liposomes, www.ondrugdelivery.com, Frederick Furness Publishing Ltd.

About The Author:

Maik W. Jornitz is a technical expert with over 35 years of experience in bioprocesses, especially sterilizing grade filtration and single-use technologies, including regulatory requirements, integrity testing, systems design, and optimization. Jornitz has published 11 books, 18 book chapters, and more than 100 scientific papers. He is a member of multiple PDA Task Forces, a former chair of the PDA Board of Directors, and the PDA’s Science Advisory Board.

Maik W. Jornitz is a technical expert with over 35 years of experience in bioprocesses, especially sterilizing grade filtration and single-use technologies, including regulatory requirements, integrity testing, systems design, and optimization. Jornitz has published 11 books, 18 book chapters, and more than 100 scientific papers. He is a member of multiple PDA Task Forces, a former chair of the PDA Board of Directors, and the PDA’s Science Advisory Board.